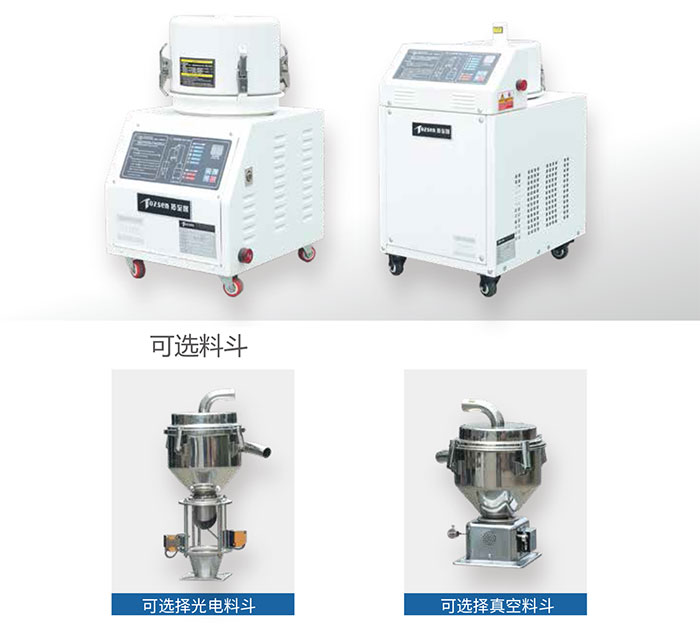

TAL-US 系列欧化三相分离式真空填料机是在原有三相分离式填料机基础上,开发设计的一款功能强大、外表美观、安装操作 TAL-US 系列欧化三相分离式真空填料机是在原有三相分离式填料机基础上,开发设计的一款功能强大、外表美观、安装操作简便的填料机。各机型采用不锈钢料门,确保原料不受污染 ; 采用高压风机为动力核心,具有不易损坏,吸力大,使用寿命长等

特点。另提供经济型机种供客户选择。TAL-US 系列真空粉体填料机,它具备 TAL-US 系列产品的一切特点,同时,另有双段风机

可供选配 ; 根据其在用户端的不同使用情形,可选择装载不同过滤器的料桶 , 适用于含粉量 30% 及 100% 的输送作业。

TAL-US | 系列

The TAL-US series Europeanized three-phase separation vacuum packing machine is a powerful, aesthetically pleasing, and easy to

install and operate packing machine developed and designed on the basis of the original three-phase separation packing machine. Each

model adopts stainless steel material doors to ensure that raw materials are not contaminated; Using high-pressure fans as the power

core, it has the characteristics of being not easily damaged, having high suction force, and long service life. We also provide economical

models for customers to choose from. The TAL-US series vacuum powder filler machine has all the characteristics of the TAL-US series

products, and there is also a dual stage fan available for optional configuration; According to its different usage on the user end, different

filter buckets can be selected for loading, suitable for conveying operations with powder content of 30% and 100%.  微处理器配记忆本使用 EEPROM, 不会丢失设定资料可永久保存; 下吸风式设计 , 滤清器下搭配旋风挡板与分离式的集尘桶 , 有效地减轻滤清器的负荷 ; 可直接配置欧化两料比例 阀阀体使用 ;

料斗可选配自动清洗装置 , 附布质滤网 , 机型后加注“C”,TAL-12U-C/CE 以上机型可额外选配储压罐,机型后面加注“A”;

可依客户需求提供经济型系列 , 降低成本 ( 经济型机配置布质滤网 , 并取消二度过滤网 );

提供多功能安装架 HMB-900 供选配******调整直径为 900mm;

提供标准型和保温型欧化集料斗 TAL-6U/12U/24U 供选配 (TAL-UGP 系列除外 );

TAL-UG 系列共有两种过滤器装置,布袋式与板式,适用于 30% 及 100% 含粉量的输送作业 , 可根据客户需求做搭配 , 储压罐 , 自动喷洗装置为标准配置 ;

TAL-1HP/2HP-UG 可选配旋风集尘器 ;

TAL-UGP 系列主机配备单、双段风机 (3.5HP 以上 ) 可供客户之需求 ;

TAL-UG 系列当输送的原料当中 , 粉碎料占 30% 以上时,可选配 14 目的不锈钢滤网 ;

改为欧规安全回路机型时,机型后加注“CE”。

The microprocessor with memory book uses EEPROM, which will not lose setting data and can be permanently saved;

The downward suction design is equipped with a cyclone baffle and a separate dust collection bucket under the filter, effectively reducing the load on the filter; Can be directly configured

with a Europeanized two material proportional valve body for use;

The hopper can be equipped with an automatic cleaning device and a fabric filter. The model can be filled with "C", and models above TAL-12U-C/CE can be additionally equipped with a

pressure storage tank. The model can be filled with "A" at the back;

We can provide economy series according to customer needs to reduce costs (economy machines are equipped with fabric filters and secondary filters are eliminated);

Provide multifunctional mounting bracket HMB-900 for optional maximum adjustment diameter of 900mm;

Provide standard and insulated Europeanized aggregate hoppers TAL-6U/12U/24U for optional configuration (excluding the TAL-UGP series);

The TAL-UG series has two types of filter devices, bag type and plate type, suitable for conveying operations with 30% and 100% powder content. They can be matched according to

customer needs. The pressure storage tank and automatic spray washing device are standard configurations;

TAL-1HP/2HP-UG can be optionally equipped with a cyclone dust collector;

The TAL-UGP series host is equipped with single and double stage fans (above 3.5HP) to meet the needs of customers;

When more than 30% of the raw materials conveyed by the TAL-UG series are crushed materials, a 14 mesh stainless steel filter can be optionally equipped;

When changing to a European safety circuit model, add "CE" after the model  |