箱型干燥机用于所有种类的聚合物材料烘干,并能同时烘干不同的材料,非常适合用于少量、多样性的原料或试模时使用,也可用于电子、电机、电镀、烤漆印刷等多行业相关产品之预热或干燥处理。

Box dryer is used for drying all kinds of polymer materials, and can dry different materials at the same time, very suitable for a small number of diverse raw materials or test the use of mold, can also be used for electronic, electric machine, electroplating, paint printing and other industries related products preheating or drying treatment.

采用精密 P.I.D. 电子温度控制,达到均匀的烘干效果 ;

高温密封门可保持一致的温度并降低热量损耗 ;

不锈铜材质的烤盘及内饰,可防止在烘干过程中污染原料 ;

优化设计,方便维修保养 ;

入风口、排风口均可调试设计,可方便调节风量 ;

24 小时定时装置,操作方便 ;

配备超温保护器,可避免超温干燥 ;

配备马达超载保护 ;

配备警示灯,可立即反应故障 ;

可依需求定制烤盘或整机特制 ;

改为欧规安全回路型时,机型后加注“CE”。

Adopt precision P.I.D. electronic temperature control, achieve uniform drying effect;

High temperature sealed door can maintain consistent temperature and reduce heat loss;

Stainless copper baking tray and lining, can prevent contamination of raw materials in the drying process;

Optimized design, convenient maintenance;

The inlet and exhaust vents can be adjusted and designed to adjust the air volume easily.

24 hours timing device, easy to operate;

Accessories overtemperature protector, can avoid overtemperature drying;

Accessories motor overload protection;

Accessory warning light, can immediately respond to failure;

Can be customized baking tray or the whole machine special;

When changing to European standard safety loop type, add "CE" after the model.

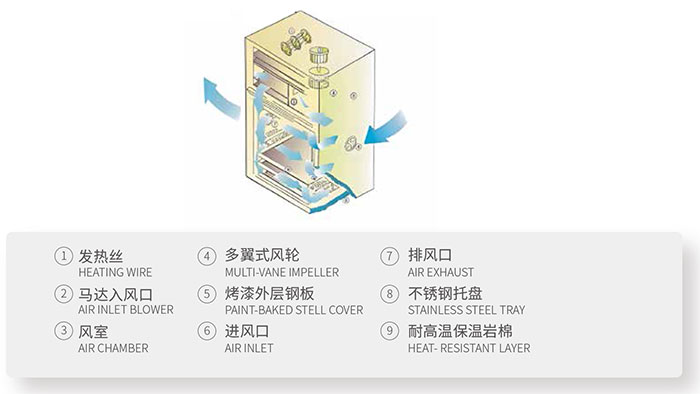

箱型干燥机中,有可移动的盘子,可将要烘干的原料放在盘子内,运行时风车迫使空气通过发热丝,经过发热丝加热后,再通过风板均匀吹进原料,潮湿的空气由排风口排出,当原料均匀烘干后,箱型干燥机停止加热。

In a box type dryer, there is a movable plate in which the raw materials to be dried can be placed. During operation, the windmill forces the air to pass through the heating wire. After being heated by the heating wire, it is evenly blown into the raw materials through the air plate. Wet air is discharged through the exhaust port. When the raw materials are evenly dried, the box type dryer stops heating.

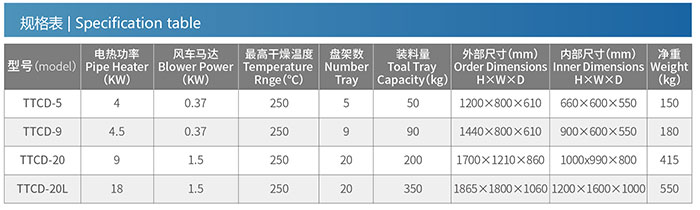

|